XTON | Technology | 5 August 2025

XTON | Technology | 5 August 2025How to Choose the Right Parts Washer for Your Workshop?

Components cleaning is a critical part for both manufacturing and repair processes across the automotive and industrial sectors. Choosing the right type of workshop parts washer directly affects your operational costs, employee safety, cleaning efficiency, and the final quality of your product or service.

High-Pressure Cabin Parts Washers

These enclosed cleaning systems ensure a clean work environment. Featuring a pneumatically lifted chamber, integrated gloves, and adjustable working height, they offer excellent comfort and safety. The operator works with dry hands and has no direct contact with chemicals. Equipped with high-pressure changeable nozzles, closed fluid circulation, and a multi-stage filtration system, these washers are efficient and economical. Their only real limitation is the size of the cleaning chamber, which varies by model.

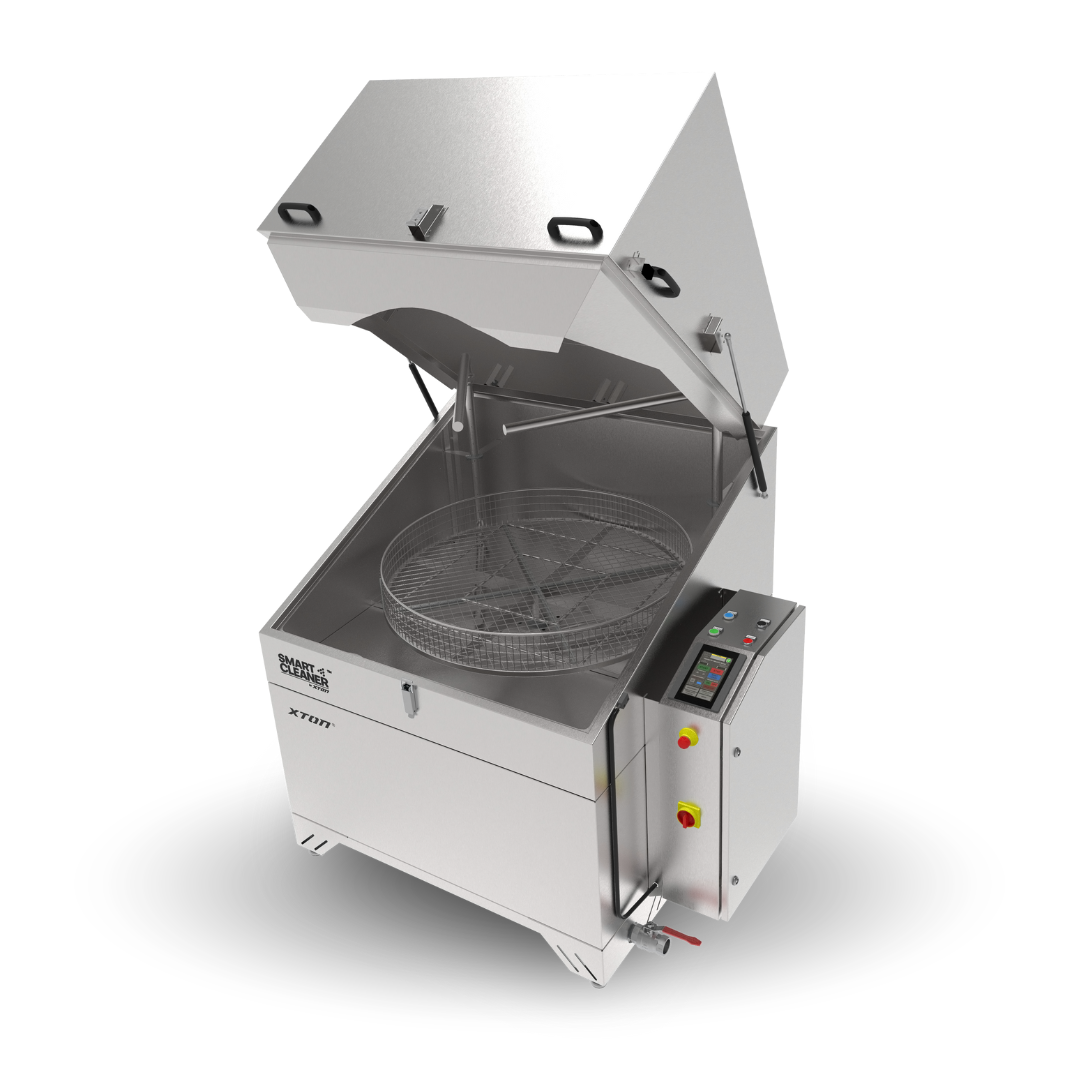

Automatic Rotary Basket Parts Washers

These washers clean multiple parts simultaneously using a rotating basket system. Ideal for large or heavily soiled parts, they work in a high-temperature closed loop, using preset wash programs. They simplify operations, improve cleanliness, and enhance workplace hygiene. However, they require more space, and some parts with complex shapes may still need manual touch-ups.

Solvent Benchtop Parts Washing Tables

Solvent-based washing tables offer a cost-effective solution for small and medium-sized workshops, ensuring thorough and efficient cleaning of small parts. These machines do not require heating of the cleaning liquids, which lowers operating costs. However, they tend to be slower and less effective. The use of chemical solvents also generates additional costs and may expose workers to harmful vapors.

Ultrasonic Parts Washers

Ideal for precision cleaning of parts with complex geometry or delicate materials. Ultrasonic washers use sound waves to remove dirt. While effective, they are expensive and limited by the chamber size.

Steam Parts Washers

Perfect for cleaning water-sensitive components like electronics or textiles. Steam washers are chemical-free and environmentally friendly, but they often require extra rinsing or air-blasting to remove loosened grime. They also offer limited throughput.

If you run a large workshop or industrial service center, consider investing in a machine park with different types of washers that complement each other. This comprehensive approach ensures optimal results when cleaning a variety of parts and tools, improving both efficiency and cleaning quality.

Key Questions Before Choosing Your Parts Washer

What size and type of parts will you be cleaning?

Part size, material, and construction matter. Ultrasonic washers suit small, delicate parts, while high-pressure cabinet washers are better for large, heavily soiled components.

What level of cleanliness is required in your industry?

Each industry has different cleanliness standards. Assess whether you need high-precision cleaning or general degreasing.

What are your purchase and operational budgets?

Factor in equipment cost, water and detergent consumption, energy use, and potential servicing expenses. A higher upfront investment may mean lower long-term operating costs.

How environmentally friendly is the machine?

Protecting worker health and minimizing emissions is crucial. Look for washers with ventilation, filtration systems, and noise control.

What about usability and maintenance? Is service support available?

Check how easy the machine is to operate and maintain. Investing in more advanced models may save time and labor in the long run.

By considering these factors, you can confidently choose the best parts washer for your workshop. The right solution will reduce costs, improve operational safety, and deliver exceptional cleaning results. Investing in the proper equipment benefits both your team and your business.

We cooperate with reputable wholesalers